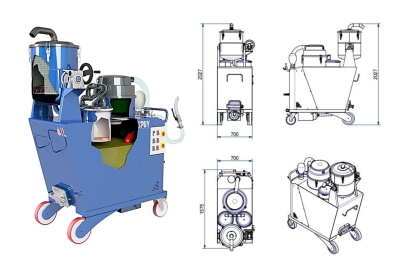

OILVAC 100 PUMP Compact Industrial Vacuum Cleaner for oil & metal chips

The suction is developed by two single-phase by-pass motors with carbon-brushes. These motors are protected inside a steel motor head, containing a sound absorbing material that minimizes noise during the service. The control panel located on the motor head has two independent switches, an indicator of clogged filter with light, that warns when the maximum level get reached and the switch of the electric and independent pump. You may find two handles located on the motor head, which allow to lift it easily to proceed to an inspection or for an easy emptying of the basket containing the metal chips collected,

There are two filters inside the filtering steel chamber: a fiber filter and a filter PPL, 300 microns, perfect to resist to the most abrasive oils. The suction system with inlet, 50, positioned below the filter allows to vacuum simultaneously solids and liquids (oils, lubricants, emulsions, metal chips, metal grain...)

The vacuumed material is separated instantly : the metal chips are collected in a galvanized sieve grid easily extractable, which allows a rapid disposal of its content. The finer shavings are retained by a second grid with filter PPL 300 micron, which purifies the oil/emulsion from any impurity. The oil passes through the grid and naturally falls, perfectly filtered, in the container.

This vacuum is equipped as standard with a manual drain valve and an electric pump which has a flow rate of 100 lts per minute. The collection unit incorporates an electronic floating device which stops the suction when the maximum level of the container has been reached.

This vacuum cleaner is made of a sturdy steel, equipped with non-marking wheels and brakes.

Advantages

Innovation

* The most compact vacuum cleaner for the cleaning of tanks in the mechanic industry

* Removable steel grid for the retention of metal shavings

Economic saving

* Collection and reuse of lubricants

* Perfect to vacuum medium quantities of material

Time saving

* Reduction of downtime

* Reduction of cost maintenance

OILVAC 200 single phase industrial vacuum for oil & chips recovery

Mobile, compact and powerful, the vacuum cleaner OILVAC 200 is the ideal machine to suck up liquid (oil or coolant) mixed with metal chips, separate the oil from the chips and recover the clean oil thanks to a powerful air flow reversal system.

The suction is provided by three by-pass 2 stage motors, placed inside a sturdy steel casing and providing high depression and operated by independent switches. It is ideal for heavy duty performance, very resistant. The suction unit is protected by a polyester filter M class Teflon 1 micron efficiency with anti adhesive treatment (oleophobe and hydrophobe) and a floating device, which automatically stops the suction when the liquid fills up the container.

The suction inlet it can Rotate 360° to easily direct the suction hose with an internally welded inlet that deflects the incoming material.

A galvanized steel sieve grid (30 litres capacity) withholds the solid material (chips and metal parts ), a second chips basket with PPL 300micron filter withholds very fine metal dust, while the clean oil goes into the lower container (capacity 200 litres). It is then possible to pump it out rapidly, simply Switch on a powerful Lowara Electric pump that pumps out rapidly the liquid through a discharge oil proof hose fitted with a gun and valve (300lt/min power).

The vacuum cleaner chassis is totally welded and it is constructed with metal 4 mm of thickness, that guarantee an Indestructible performance during the years.

It is equipped with a tool basket also providing a support for tools and hoses when not used, and equipped with braking polyurethane castors, and forklift intakes to easily transport the machine.

Applications

Suction from machine tools of liquids, (mainly oils and coolants mixed with metal chips or other solid material)

Filtration and recovery of cutting oil and coolant liquid

Rapid collection or disposal of the filtered liquid

Reduced stand-by time of machine tools

Saving by recovering and using several times the same oil and coolant

OILVAC 200 T three phase Industrial vacuum for oil & chips recovery

The suction unit is a turbine motor of the “side channel blower” type: the fan being directly shafted on the motor shaft, this type of motor requires no transmission system and provides a performance of 2.850 RPM. It is thus completely maintenance free, ideal for non-stop and heavy duty performance (providing extra vacuum, up to 3200 mm. H2O depression), very silent and resistant, matching an IP 55 level. The suction unit is protected by A polyester filter and a floating device, automatically stopping the suction when the liquid fills up the container.

A metal sieve grid (30 litres capacity) withholds the solid material (chips and metal parts), ), a second chips basket with PPL 300micron filter withholds very fine metal dust, while the clean oil goes into the lower container (capacity 200 litres).

It is then possible to pump it out rapidly, through a powerful electric pump (300 litres per minute, fitted with a 2 mt. discharge oil proof hose fitted with a gun and valve).

The collection tank is made of polyester coated steel 4mm of thickness, and has a slanted shape in order to secure complete disposal of the liquid inside; accessory baskets provide a support for tools and hoses when not used, and a bolted panel enables easy cleaning of the collection tank. The vacuum cleaner is mounted on a solid steel trolley with forklifts intakes, equipped with braking and turning wheels.

Applications

Suction from machine tools of oils and coolants mixed with metal chips or other solid material

Filtration and recovery of cutting oil and coolant liquid

Rapid collection or disposal of the filtered liquid

Reduced stand-by time of machine tools

Saving by recovering and using several times the same oil and coolant Possibility to suck up and pump out simultaneously

Need for just one operator to use the machine

OILVAC 450 DF Industrial Vacuum Cleaner for Oil & metal Chips Recovery

The suction unit is a turbine motor of the “side channel blower” type: the fan being directly shafted on the motor shaft, this type of motor requires no transmission system and provides a performance of 2.850 RPM. It is thus completely maintenance free, ideal for non-stop and heavy duty performance (providing extra vacuum, up to 3200 mm H2O depression), very silent and resistant, matching an IP 55 level. The suction unit is protected by A PPL filter and a electric floating device automatically stopping the suction when the liquid fills up the container.

A metal sieve grid (65 liters capacity) withholds the solid material (chips and metal parts), collected into a special hopper with a user-friendly mechanism enables to tilt the hopper and discharge easily the collected solid material, while the clean oil goes into the lower container (capacity 450 litres).

A second chips basket is available of the DF series capable of filter up to 50 micron the oil for very fine metal dust.

It is then possible to pump it out rapidly, through a powerful electric pump (300 litres per minute, fitted with a 2 mt. discharge oil proof hose fitted with a gun and valve).

The collection tank is made of polyester coated steel 4mm of thickness, and has a slanted shape in order to secure complete disposal of the liquid inside; accessory baskets provide a support for tools and hoses when not used, and a bolted panel enables easy cleaning of the collection tank. The vacuum cleaner is mounted on a solid steel trolley with forklift intakes, equipped with braking and turning wheels.

Applications and Advantages

* Suction from machine tools of oils and coolants mixed with metal chips or other solid material

* Filtration and recovery of cutting oil and coolant liquid

* Rapid collection or disposal of the filtered liquid

* Reduced stand-by time of machine tools

* Saving by recovering and using several times the same oil and coolant

* Possibility to suck up and pump out simultaneously

* Need for just one operator to use the machine