BEST 1

WHY CHOOSE THE "BEST-1"?

The function of general oil-water separators sold on the market only separates oil from water, but coolant contains a large number of bacteria, which will lead to deterioration and stench of coolant. Our" BEST-1" has functions to filter impurities, separate oil from water, sterilize and deodorize by an additionally fitted ozone apparatus. It also can effectively extend the service life of customers’ coolant, to enhance the machining precision, extend tool life, significantly reduce times for staff to clean and replace the cistern.

FUNCTIONAL FEATURES

The impurity substance is filtered

The oil water separation.

Ozone disinfection.

Cutting fluid quality purification

No supplies, Reduces costs.

Raise processing accuracy.

Safeguards your health and improves the environment.

In stock

CHIPVAC 200 single phase Industrial vacuum cleaner for dust, liquid and solid material

The suction is provided by three by-pass motors, using carbon brushes, operated by independent switches and placed inside a sturdy steel casing . The motor head is filled with noise reducing material, in order to limit as much as possible the level of noise, and designed in order to convey the exhaust air towards the ground, so as not to bother the user and not to raise possible dust in the neighbouring area.

The filter is placed and protected inside the steel filter chamber; the filter is made of polyester, tailored with stars in order to increase the filter surface (1,4 m2), and has a high filtration efficiency (3 micron). A manual filter shaker enables the user to clean the filter efficiently, by a vertical shaking movement, so as to detach most of the dust and maintain the filter clean, in order to increase its life and maintain the suction performance of the machine. The frontal aluminium die-cast suction inlet (Ø80 mm. diameter), placed below the filter, makes it possible to vacuum at the same time dust, solid and liquid material, with no need to change or take out the filter

The vacuumed material is placed inside a large container mounted on wheels (300 lt. of capacity), which makes it possible to dispose easily and safely of the sucked material thanks to the front discharge.

The vacuum is mounted on a sturdy steel chassis with two pivoting wheels, one of which with brakes, and with forklift intakes. All the metal parts of the vacuum are epoxy painted. Industrial construction 4mm of thickness. With the aid of a forklift is simplified the operation of empting the vacuumed materials like Metal chips. It is possible to introduce metal grid for the separation of metal chips which remain in the upper part and the liquids (like oils) that will stay in the lower part of the container. A 1” discharge valve is available to empty the liquids container.

Perfect for transport and rapid unloading with forklift

Oil and metal chips separator, galvanized steel made.

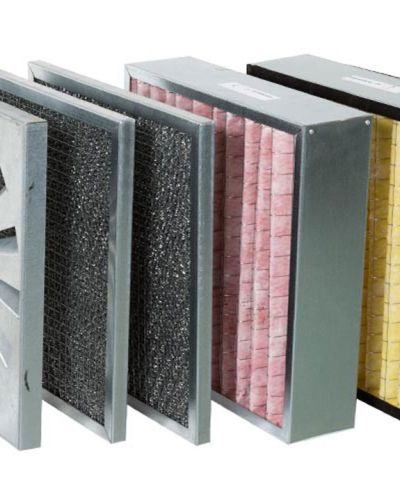

Icarus L

Icarus is a static exhaust fan for filtration of air containing oil mists, micro-mists and smokes, generated from coolants (both emulsion or neat oil), which can be used on every kind of machine tool and for every removal machinery.

Icarus is available in three sizes with flowrate from 600 to 2.000 m3/h with different filtration efficiency combination, up to performances of 99,97%.

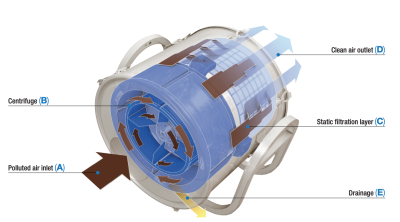

DARWIN D3000D oil mist collector

Darwin series is a range of centrifugal filters for cleaning air containing oil mists, micro-mists and smokes produced when using coolants (emulsion or neat oil). It can be used with a majority of machine tools for all machining processes. It is available in 4 sizes with three different, interchangeable filtration technologies.

Throughputs available are from 600 to 3.000 m3/h, with different combination for increasing filtration efficiency, up to 99,97%.

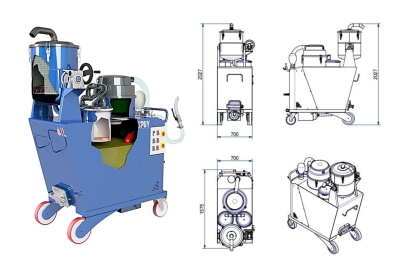

OILVAC 200 single phase industrial vacuum for oil & chips recovery

Mobile, compact and powerful, the vacuum cleaner OILVAC 200 is the ideal machine to suck up liquid (oil or coolant) mixed with metal chips, separate the oil from the chips and recover the clean oil thanks to a powerful air flow reversal system.

The suction is provided by three by-pass 2 stage motors, placed inside a sturdy steel casing and providing high depression and operated by independent switches. It is ideal for heavy duty performance, very resistant. The suction unit is protected by a polyester filter M class Teflon 1 micron efficiency with anti adhesive treatment (oleophobe and hydrophobe) and a floating device, which automatically stops the suction when the liquid fills up the container.

The suction inlet it can Rotate 360° to easily direct the suction hose with an internally welded inlet that deflects the incoming material.

A galvanized steel sieve grid (30 litres capacity) withholds the solid material (chips and metal parts ), a second chips basket with PPL 300micron filter withholds very fine metal dust, while the clean oil goes into the lower container (capacity 200 litres). It is then possible to pump it out rapidly, simply Switch on a powerful Lowara Electric pump that pumps out rapidly the liquid through a discharge oil proof hose fitted with a gun and valve (300lt/min power).

The vacuum cleaner chassis is totally welded and it is constructed with metal 4 mm of thickness, that guarantee an Indestructible performance during the years.

It is equipped with a tool basket also providing a support for tools and hoses when not used, and equipped with braking polyurethane castors, and forklift intakes to easily transport the machine.

Applications

Suction from machine tools of liquids, (mainly oils and coolants mixed with metal chips or other solid material)

Filtration and recovery of cutting oil and coolant liquid

Rapid collection or disposal of the filtered liquid

Reduced stand-by time of machine tools

Saving by recovering and using several times the same oil and coolant

Combi 125 ultrasonic cleaning system

This is our most popular ultrasonic cleaning system which is manufactured as a single and multistage machine depending on the cleaning application.

We produce the ultrasonic cleaning system in stainless steel for automotive, aerospace, pharmaceutical and a wide-range of other manufacturing industries. A solid frame construction and welded tanks, its completely insulated on both tank and cabinet to reduce heat loss and noise-pollution.

Available standard modules:

- Ultrasonic cleaning

- Venturi jet-nozzle turbulence

- Spray washing chamber

- Rinsing with air-bubble turbulence

- Hot air drying

- Vacuum drying.

Volume: 125 L

Tank size: 700x450x400 mm

Basket size: 680x430x350 mm

Max. basket weight: 150 kg

Frequency: 25 or 40 Khz

Ultrasonic effect: 1500 W

Temperature: 0 – 85 °C

Heating effect: 2700 W

Power supply: 16 A

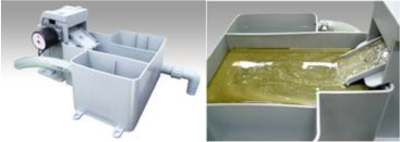

OS-Q2 Separator

Innovative high-quality oilseparator constructed in stainless steel. The oilseparator is designe with a four-chamber labyrint system which ensures efficient separation of the oils.

This gives the process fluid optimal conditions for separation the oils which are removed from the tank units using a highly-efficient suction head. This ensures that the process fluids are always free of unwanted oils which can affect operation and process fluid life-cycle.

Applications:

Tank units from washing systems

Machining centers

Process fluid tanks

Waste water treatment

OILVAC 200 T three phase Industrial vacuum for oil & chips recovery

The suction unit is a turbine motor of the “side channel blower” type: the fan being directly shafted on the motor shaft, this type of motor requires no transmission system and provides a performance of 2.850 RPM. It is thus completely maintenance free, ideal for non-stop and heavy duty performance (providing extra vacuum, up to 3200 mm. H2O depression), very silent and resistant, matching an IP 55 level. The suction unit is protected by A polyester filter and a floating device, automatically stopping the suction when the liquid fills up the container.

A metal sieve grid (30 litres capacity) withholds the solid material (chips and metal parts), ), a second chips basket with PPL 300micron filter withholds very fine metal dust, while the clean oil goes into the lower container (capacity 200 litres).

It is then possible to pump it out rapidly, through a powerful electric pump (300 litres per minute, fitted with a 2 mt. discharge oil proof hose fitted with a gun and valve).

The collection tank is made of polyester coated steel 4mm of thickness, and has a slanted shape in order to secure complete disposal of the liquid inside; accessory baskets provide a support for tools and hoses when not used, and a bolted panel enables easy cleaning of the collection tank. The vacuum cleaner is mounted on a solid steel trolley with forklifts intakes, equipped with braking and turning wheels.

Applications

Suction from machine tools of oils and coolants mixed with metal chips or other solid material

Filtration and recovery of cutting oil and coolant liquid

Rapid collection or disposal of the filtered liquid

Reduced stand-by time of machine tools

Saving by recovering and using several times the same oil and coolant Possibility to suck up and pump out simultaneously

Need for just one operator to use the machine

OILVAC 450 DF Industrial Vacuum Cleaner for Oil & metal Chips Recovery

The suction unit is a turbine motor of the “side channel blower” type: the fan being directly shafted on the motor shaft, this type of motor requires no transmission system and provides a performance of 2.850 RPM. It is thus completely maintenance free, ideal for non-stop and heavy duty performance (providing extra vacuum, up to 3200 mm H2O depression), very silent and resistant, matching an IP 55 level. The suction unit is protected by A PPL filter and a electric floating device automatically stopping the suction when the liquid fills up the container.

A metal sieve grid (65 liters capacity) withholds the solid material (chips and metal parts), collected into a special hopper with a user-friendly mechanism enables to tilt the hopper and discharge easily the collected solid material, while the clean oil goes into the lower container (capacity 450 litres).

A second chips basket is available of the DF series capable of filter up to 50 micron the oil for very fine metal dust.

It is then possible to pump it out rapidly, through a powerful electric pump (300 litres per minute, fitted with a 2 mt. discharge oil proof hose fitted with a gun and valve).

The collection tank is made of polyester coated steel 4mm of thickness, and has a slanted shape in order to secure complete disposal of the liquid inside; accessory baskets provide a support for tools and hoses when not used, and a bolted panel enables easy cleaning of the collection tank. The vacuum cleaner is mounted on a solid steel trolley with forklift intakes, equipped with braking and turning wheels.

Applications and Advantages

* Suction from machine tools of oils and coolants mixed with metal chips or other solid material

* Filtration and recovery of cutting oil and coolant liquid

* Rapid collection or disposal of the filtered liquid

* Reduced stand-by time of machine tools

* Saving by recovering and using several times the same oil and coolant

* Possibility to suck up and pump out simultaneously

* Need for just one operator to use the machine