filtration systems

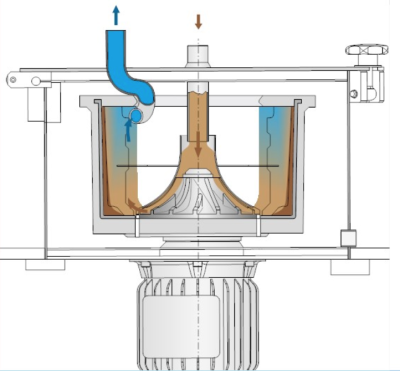

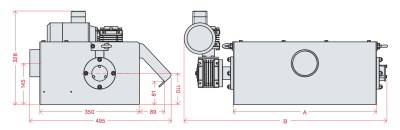

Separator U-15

* fluid-dynamically designed accelerator hub

* direct drive

* peeler tube, backflow head 5 m

* residual liquid drain at standstill

Power: 4 kW

Rotor volume: 15 l

Sludge capacity: 12 kg

Volume flow: 120 l/min (7,2 m³)

Acceleration: 1960 x g

With its large effective rotor diameter, the high-performance 4 kW drive, and thanks to the special inlet hub the separator U-15 achieves a very good separation level of down to 3 µm. The cleaned medium leaves the separator under pressure (5 m pumping head), the sludge is dry and can be removed without residual liquid. Due to the direct drive system the separator is very compact, hence ideally suited for use in compact coolant systems or as a stand-alone solution directly placed at machine tanks.

Application: all kinds of industrial fluids, typically mechanical processing (coolant lubricant emulsions and oils, washing or vibratory grinding fluids), surface treatment or glass grinding. The separator U-15 is also available in 3-phase version (simultaneous separation of a light secondary liquid phase, e.g. tramp oil)

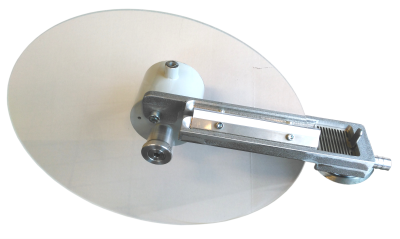

This Oil Skimmer removes unwanted leak oils and other contaminants from the surface of the cooling lubricant.

Capacity approx. 20 liter/Hour.

Simple Use.

Quick and easy disassembly / assembly.

Small Enclosure dimensions make it easy to position the CNC machines.

Supplied “ready to run” incl. standard 320mm Disc (Plexiglas) Can be delivered with Alloy-Disc + electrolytic ceramic surface.

Also available with Magnet mount (picture).

D-models special developed for production with high amounts of leak-oils in the surface of Emulsion. The Nimatic Oil Skimmer This model is special designed for heavy leaking machines, with oiled feeder, but can be used in all heavy leaking situations.

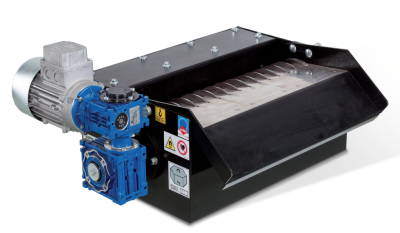

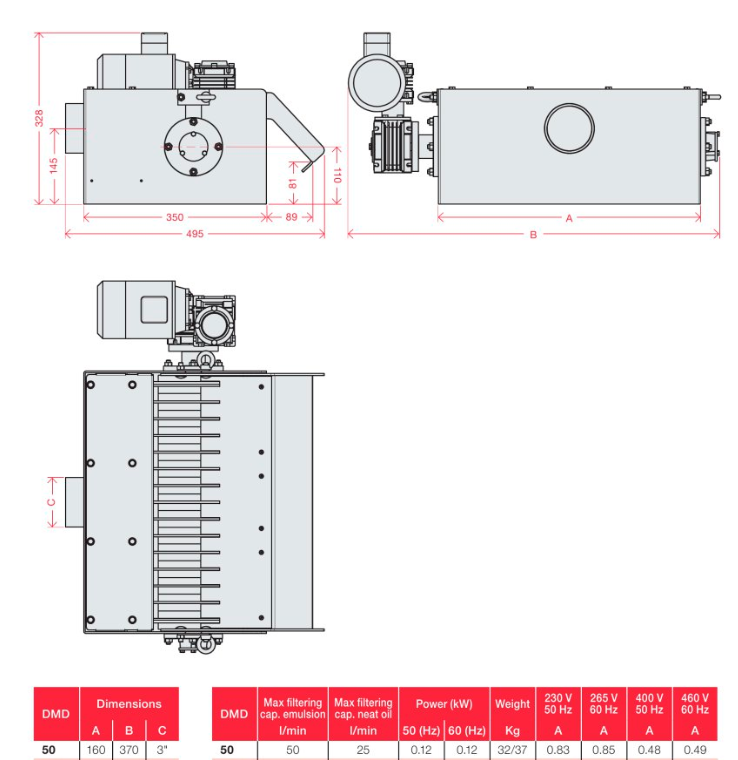

DMD 50 rotating discs magnetic separator

DMD is a rotating magnetic discs separator for coolants used during industrial machining contaminated by magnetic particles.

DMD series is available in 7 standard models for flowrates ranging from 50 to 400 l/min of emulsion and from 25 to 200 l/min of neat oil.

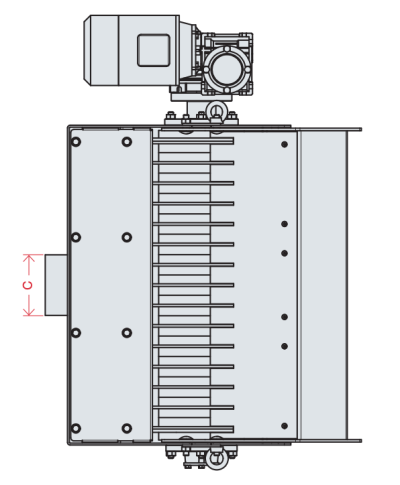

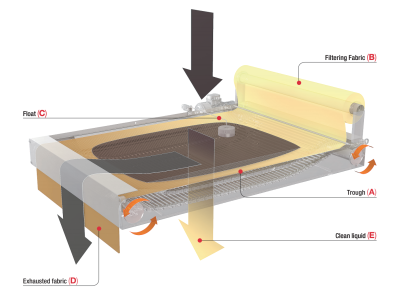

Flat bed coolant filter DTE 150

Detex is a flat bed coolant filter, using nonwoven fabric for eliminating magnetic and nonmagnetic particles from neat oil and emulsion. Filtration degree can be determined by the choice of the fabric, ranging from 10 to 50 micron, granting the highest level of filtration. Detex is available in 12 sizes, with a flowrate capacity from 50 to 400 l/min of emulsion and from 25 to 200 l/min of neat oil.

No tank, no electrical board, no pump.

Fabric filtration guarantees a high filtration efficiency with a limited initial investment.

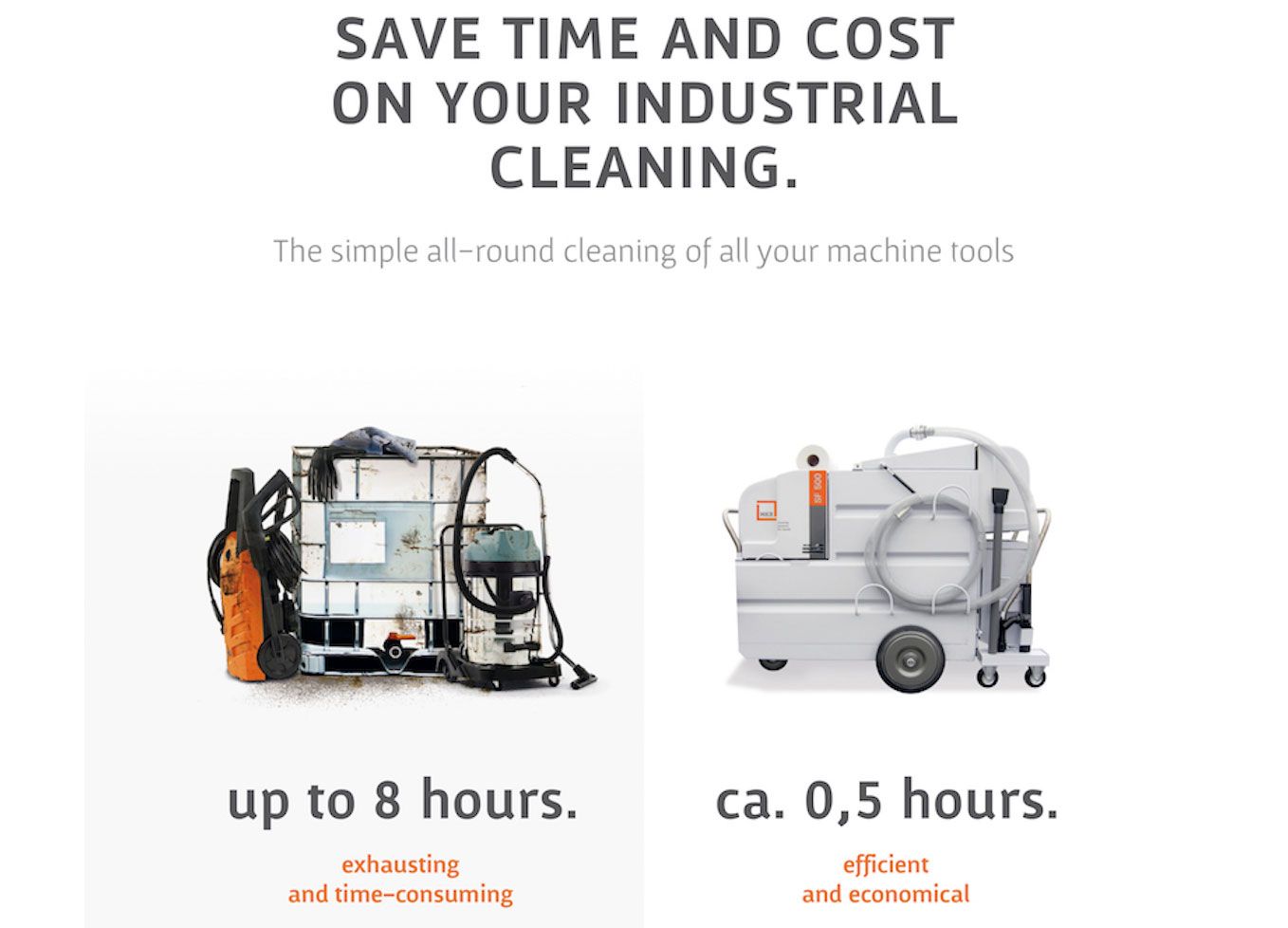

OILVAC 100 PUMP Compact Industrial Vacuum Cleaner for oil & metal chips

The suction is developed by two single-phase by-pass motors with carbon-brushes. These motors are protected inside a steel motor head, containing a sound absorbing material that minimizes noise during the service. The control panel located on the motor head has two independent switches, an indicator of clogged filter with light, that warns when the maximum level get reached and the switch of the electric and independent pump. You may find two handles located on the motor head, which allow to lift it easily to proceed to an inspection or for an easy emptying of the basket containing the metal chips collected,

There are two filters inside the filtering steel chamber: a fiber filter and a filter PPL, 300 microns, perfect to resist to the most abrasive oils. The suction system with inlet, 50, positioned below the filter allows to vacuum simultaneously solids and liquids (oils, lubricants, emulsions, metal chips, metal grain...)

The vacuumed material is separated instantly : the metal chips are collected in a galvanized sieve grid easily extractable, which allows a rapid disposal of its content. The finer shavings are retained by a second grid with filter PPL 300 micron, which purifies the oil/emulsion from any impurity. The oil passes through the grid and naturally falls, perfectly filtered, in the container.

This vacuum is equipped as standard with a manual drain valve and an electric pump which has a flow rate of 100 lts per minute. The collection unit incorporates an electronic floating device which stops the suction when the maximum level of the container has been reached.

This vacuum cleaner is made of a sturdy steel, equipped with non-marking wheels and brakes.

Advantages

Innovation

* The most compact vacuum cleaner for the cleaning of tanks in the mechanic industry

* Removable steel grid for the retention of metal shavings

Economic saving

* Collection and reuse of lubricants

* Perfect to vacuum medium quantities of material

Time saving

* Reduction of downtime

* Reduction of cost maintenance

CHIPVAC 200 single phase Industrial vacuum cleaner for dust, liquid and solid material

The suction is provided by three by-pass motors, using carbon brushes, operated by independent switches and placed inside a sturdy steel casing . The motor head is filled with noise reducing material, in order to limit as much as possible the level of noise, and designed in order to convey the exhaust air towards the ground, so as not to bother the user and not to raise possible dust in the neighbouring area.

The filter is placed and protected inside the steel filter chamber; the filter is made of polyester, tailored with stars in order to increase the filter surface (1,4 m2), and has a high filtration efficiency (3 micron). A manual filter shaker enables the user to clean the filter efficiently, by a vertical shaking movement, so as to detach most of the dust and maintain the filter clean, in order to increase its life and maintain the suction performance of the machine. The frontal aluminium die-cast suction inlet (Ø80 mm. diameter), placed below the filter, makes it possible to vacuum at the same time dust, solid and liquid material, with no need to change or take out the filter

The vacuumed material is placed inside a large container mounted on wheels (300 lt. of capacity), which makes it possible to dispose easily and safely of the sucked material thanks to the front discharge.

The vacuum is mounted on a sturdy steel chassis with two pivoting wheels, one of which with brakes, and with forklift intakes. All the metal parts of the vacuum are epoxy painted. Industrial construction 4mm of thickness. With the aid of a forklift is simplified the operation of empting the vacuumed materials like Metal chips. It is possible to introduce metal grid for the separation of metal chips which remain in the upper part and the liquids (like oils) that will stay in the lower part of the container. A 1” discharge valve is available to empty the liquids container.

Perfect for transport and rapid unloading with forklift

Oil and metal chips separator, galvanized steel made.

Icarus L

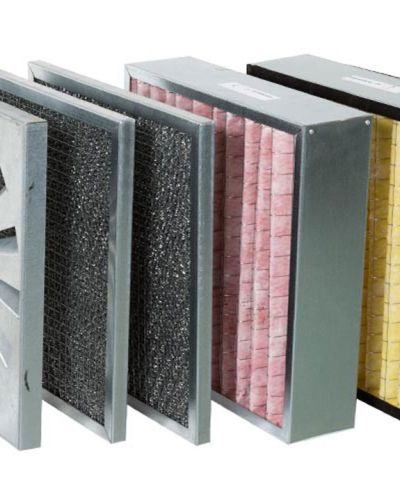

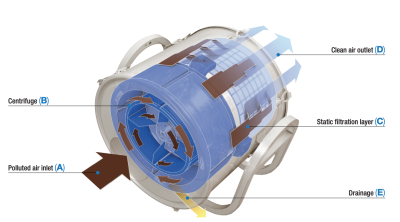

Icarus is a static exhaust fan for filtration of air containing oil mists, micro-mists and smokes, generated from coolants (both emulsion or neat oil), which can be used on every kind of machine tool and for every removal machinery.

Icarus is available in three sizes with flowrate from 600 to 2.000 m3/h with different filtration efficiency combination, up to performances of 99,97%.

DARWIN D3000D oil mist collector

Darwin series is a range of centrifugal filters for cleaning air containing oil mists, micro-mists and smokes produced when using coolants (emulsion or neat oil). It can be used with a majority of machine tools for all machining processes. It is available in 4 sizes with three different, interchangeable filtration technologies.

Throughputs available are from 600 to 3.000 m3/h, with different combination for increasing filtration efficiency, up to 99,97%.