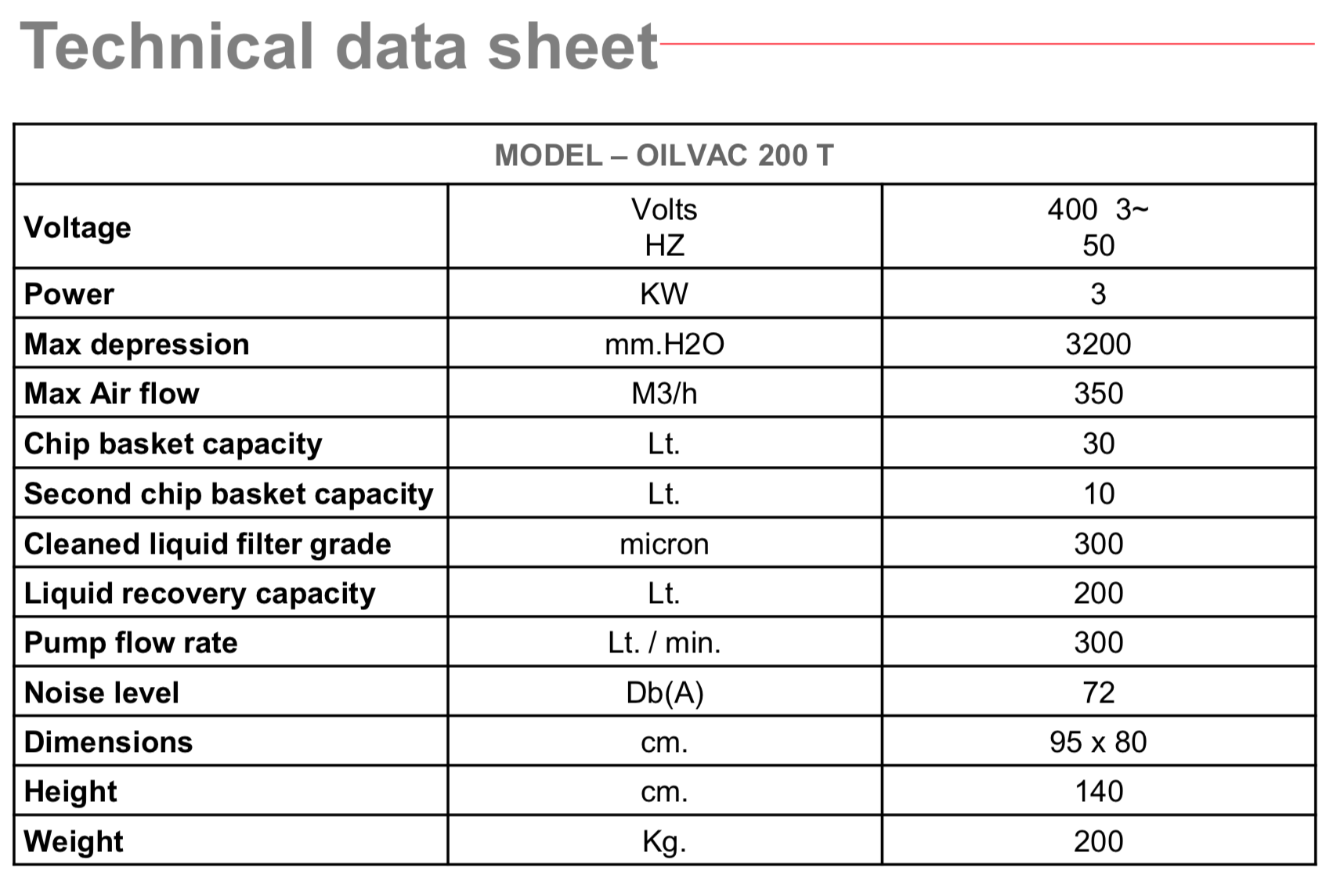

OILVAC 200 T three phase Industrial vacuum for oil & chips recovery

The suction unit is a turbine motor of the “side channel blower” type: the fan being directly shafted on the motor shaft, this type of motor requires no transmission system and provides a performance of 2.850 RPM. It is thus completely maintenance free, ideal for non-stop and heavy duty performance (providing extra vacuum, up to 3200 mm. H2O depression), very silent and resistant, matching an IP 55 level. The suction unit is protected by A polyester filter and a floating device, automatically stopping the suction when the liquid fills up the container.

A metal sieve grid (30 litres capacity) withholds the solid material (chips and metal parts), ), a second chips basket with PPL 300micron filter withholds very fine metal dust, while the clean oil goes into the lower container (capacity 200 litres).

It is then possible to pump it out rapidly, through a powerful electric pump (300 litres per minute, fitted with a 2 mt. discharge oil proof hose fitted with a gun and valve).

The collection tank is made of polyester coated steel 4mm of thickness, and has a slanted shape in order to secure complete disposal of the liquid inside; accessory baskets provide a support for tools and hoses when not used, and a bolted panel enables easy cleaning of the collection tank. The vacuum cleaner is mounted on a solid steel trolley with forklifts intakes, equipped with braking and turning wheels.

Applications

Suction from machine tools of oils and coolants mixed with metal chips or other solid material

Filtration and recovery of cutting oil and coolant liquid

Rapid collection or disposal of the filtered liquid

Reduced stand-by time of machine tools

Saving by recovering and using several times the same oil and coolant Possibility to suck up and pump out simultaneously

Need for just one operator to use the machine