Date: 03 Oct 2018

OIL MIST COLLECTION, OIL MIST FILTRATION SYSTEM, DUST COLLECTION

Darwin is a range of centrifugal oil mist filters for cleaning air containing oil mists, micro-mists and smokes produced when using coolants (emulsion or neat oil). It has been designed to be mounted on or off the machine.

It is available in 4 sizes, for a flowrate up to 3000 m³/h, with 3 different interchangeable filtration technologies.

It can be mounted horizontally or vertically

Double filtration system

Easy installation

Stainless steel version

It is available in 4 sizes with three different, interchangeable filtration technologies:

Turbina: suitable for surface machining also in the presence of heavy particulates

Mono centrifuge: suitable for all machining processes

Double centrifuge: suitable for all machining processes above all heavy machining conditions like use of high pressure.

Throughputs available are from 600 to 3.000 m3/h, with different combination for increasing filtration efficiency, up to 99,97%.

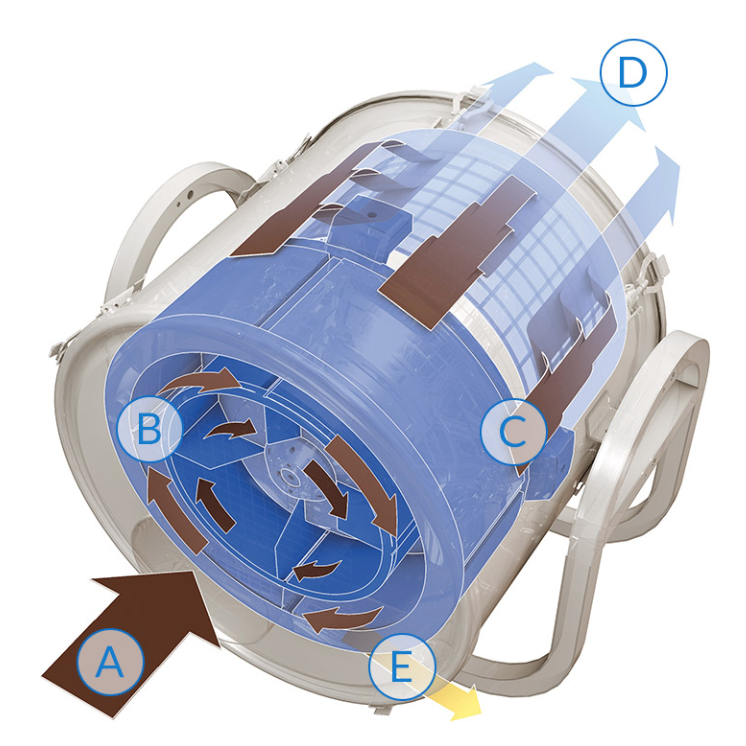

OPERATION

>> Polluted air is drawn into the system (A) thanks to the depression generated from the rotation of the centrifuge (B), which gives the air a swirling movement.

>> Air passes through the special expanded polyurethane foam inserts positioned in the centrifuge (only in mono and double version) and then into a net. The combination of all these elements facilitates the re-coalescing of oil particles – including the finer ones.

>> Air crosses a further static filtration layer (C) before being re-introduced into the working environment (D). The re-condensed liquid is eliminated through the drainage tube in constant positive pressure (E).

>> Darwin series grants a filtration efficiency of over 95%, also for pollutant particles below one micron; this efficiency rate can be increased to 99,97% with the use of an absolute post-filter (HEPA FILTER) according to EN 1822 norms.

Post comment